Home - Crane History

Crane History

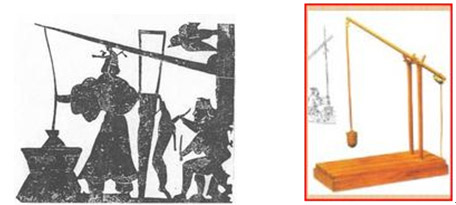

Ancient Greek scientist Archimedes once said: "Give me a place to stand and a lever long enough and I will move the entire planet. The irrigated farmland began as early as the Spring and Autumn Period and Kap Shui Jie Gao, is the use of this principle. Jie Gao said the history of the earliest of the jib crane. Its structure, the equivalent of an ordinary lever. The middle of the extension bar in its cross by the vertical wood support or hanging up, one end of the crossbar is connected to a straight rod with a drain device, and the other end tied or hanging on a heavy stone. When not Kap Shui low stone position (potential small); When To Kap Shui force Straight and drain to press down at the same time. The other end of the stone position (potential increase) increased. When a the drain sink full, let the other end of the stone down, the potential energy stored by the stone thus transformed: leverage, it may be upgraded to drain. In this way, the Kap Shui process the direction of the applied force is down. Downward force can make use of a person's weight, which gives a feeling of relaxed, people carrying water will greatly reduce the degree of fatigue. This water lifting tool, is the ancient Chinese society, a major irrigation machinery. Three Kingdoms period hindsight it improved, which invented the waterwheel, also called Kongming car. |

|

| Jie Gao | Waterwheel |

According to the lever principle, the ancient Greeks (3rd century BC) produced the first mechanical structure of the crane, the crane, the two fixed pulley and a movable pulley.

|

| Ancient Greek crane |

In the 14th century, Western Europe human and animal power driven rotating jib crane. The early 19th century, there has been a bridge crane; crane wear parts such as shafts, gears and spreader adopted the manufacture of metallic materials, and began using hydraulic drive. The late 19th century, steam-driven crane gradually replaced the hydraulic drive of the crane. Demag at the 1873 World's Fair in Vienna to launch the world's first steam-driven crane, the crane already has a prototype of the modern crane lifting weight 16t, was no electricity, the use of the steam engine as a power source, the structural parts are riveted . Day from the launch of the world's first steam crane, DEMAG has to stand up in the most sophisticated of the world's top crane brand. From that day began, more than 100 years Demag crane design philosophy has always been to lead the world in the latest trend.

|

| The Demag's first steam-driven crane |

Began in the 1920s, due to the rapid industrial development of the electrical industry and internal combustion engine to the electric motor or internal combustion engine-powered device the various cranes basic formation. In 1938 the yale invented wire rope gourd. 1944 shepard-niles gourd lift the atomic bomb in New Mexico to do the test. 1969 Power Electronics International, Inc. Developed with reduction drive gourd. 1983, the world's largest bridge crane was put into use in Brazil Itaipu power station.

The late 20th century to the recent years of the world crane industry is developing rapidly, the crane industry in China after the course of development of the heavy-lift from imitation to independent research and development, from small deadweight. To the introduction of foreign advanced technology in the early stages of development, through digestion and absorption, as I used to. Late to improve the product or innovation, manufacturing crane products more in line with China's national conditions. Crane the following trends: 1, light; 2, modular intelligent; 3; 4, product constructed novel, beautiful; 5, after-sales service fast and specialization humane. Types of cranes is growing, now mainly formed a bridge crane, gantry crane and light small crane and several other categories, each category can be divided into a number of small classes. Product areas related to iron and steel, coal, electric power, metallurgy, petroleum, chemical, aerospace, shipbuilding, military, machinery manufacturing, rail transportation and other related to the various sectors of the national economy and people's livelihood. With the increasing levels of machinery and equipment manufacturing, lifting the industry will move to a higher level, and create a more state-of-the-art performance and quality, safe and reliable products.

ATQ series lightweight self-developed by our company into the 21st century, crane, reached the international advanced level. The machine adopts modular design, PLC programming control and frequency control, the latest requirements of the safety monitoring system installed can access industry. Compared with the traditional bridge crane, ATQ series crane is light weight and reduce to about 1/3; headroom low lifting height, you can save plant height and civil investment; running smoothly, the impact of plant extended The service life of the plant;, low noise, measured lower than 60dB, more conducive to the physical and mental health of the plant workers, in line with today's user-friendly, ergonomic design concept. As ATQ crane scale, mass production, its cost advantage will be further apparent more advantages compared with traditional overhead crane, will eventually replace the traditional overhead crane.

|

| Our independent research ATQ lightweight crane |